by Norm Wilson N6JV – Visit the museum at N6JV.com

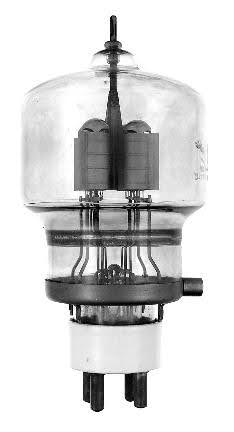

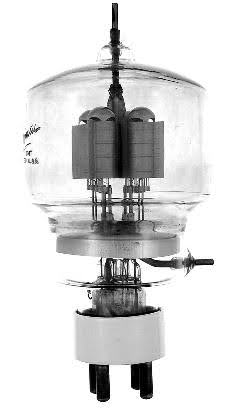

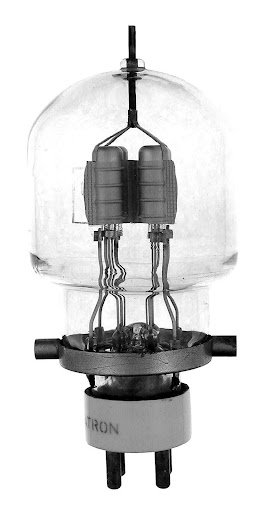

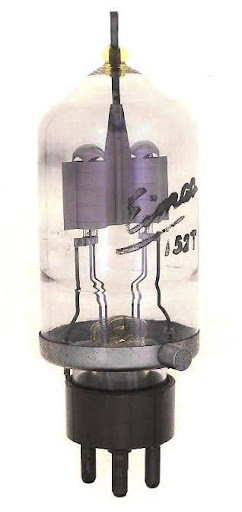

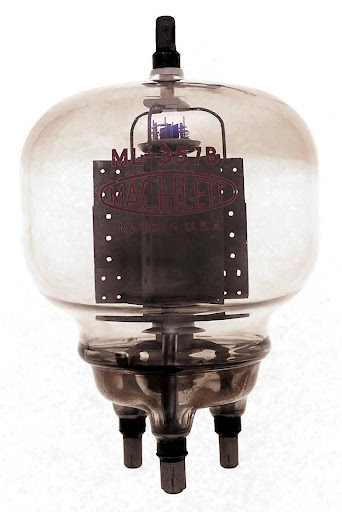

WE-357A/B

Western Electric was one of the first makers of vacuum tubes. After World War I, surplus tubes were made available to the public and commercial users. Western Electric also became a manufacturer of tubes for their own products including broadcast transmitters.

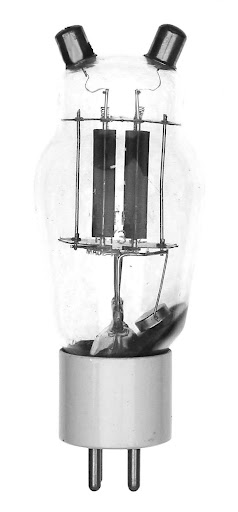

In 1928, new Western Electric 500-watt transmitters were installed in my area at KMJ and KFBK. I have 212D tubes from the finals of these transmitters. A new tube was introduced in 1939 designed for general use in broadcasting. The 357A is a 350-watt dissipation triode designed for operation at full power up to 100 MHz and up to 150 MHz at reduced power. Filament power is 10 volts at 10 amps and the plate rating is 4000 volts at 500 ma maximum. Class C output was a maximum of 1250 watts. In 1941, the plate coating was changed to Zirconium resulting in a plate dissipation of 400 watts. The new tube was the 357B.

The tube was designed to have the minimum internal length of electrodes. The internal connections were all very thick to allow the tube to be used at high frequency and dissipate heat. The tube has no internal insulators which also improves operation at high frequency. A special 3 pin socket was made just for this type,

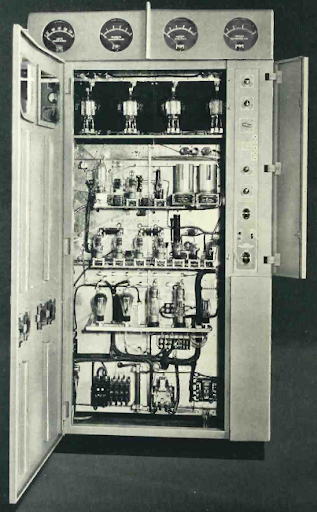

The 357A was used in the Western Electric AM transmitters 430B1 (100 watts) up to the 443A1 (1000 watts) that used 4 of these tubes and is shown in this article. The 357A/B was also used in FM transmitters as drivers in the 50 KW transmitters. Continental Electronics incorporated these tubes as drivers in their famous 105 transmitter that had an output of 1,000,000 watts.